Types and specifications of drag conveyors

What are drag conveyors? Drag conveyors are like most various conveyors with respect to action - a motor controls a ceaseless single or twofold deserted chain of flights that pulls or "drags" materia

Aditya Pandey

What are drag conveyors?

Drag conveyors are like most various conveyors with respect to action - a motor controls a ceaseless single or twofold deserted chain of flights that pulls or "drags" material through the lower part of the transport. The chain can be fairly encased, but in all cases, there ought to be a kind of housing to allow material to be dragged by the excursions to the power source. These flights, alluded to similarly as paddles or scrubbers, are specific in that they can use around half of the available space inside the transport for material turn of events, instead of the standard 20-45% of other transport types. They are, thusly, prepared to move more material with less power and are generally a useful decision for transport. The openings between every paddle are enough tremendous to consider different bays and top-stacking of materials into the transport, pursuing it a mind boggling multi-reason decision.

Drag conveyors are the most fitting for dry, free-streaming materials and are by and large important for the cultivating, rail line, engineered, concrete, and various applications which require metering and compelling advancement of things. They can be inclined as well as level, in any case, their paddles ought to be planned for vertical passing on at whatever point needed. They are quite easy to execute into plants and can be intended to have various straights/power sources, making them an amazing fitting and-play transport type. They can moreover be used couple with other open conveyors to help with recuperating any lost material, giving them additional applications in reusing, regular protection, and total limits.

Types of drag conveyors

There are a couple of crucial sorts of drag conveyors open to buyers, and this section will detail these sorts for those fascinated. This summary isn't exhaustive, as there are maker unequivocal sorts not showed here, yet understand that specific and custom drag conveyors exist.

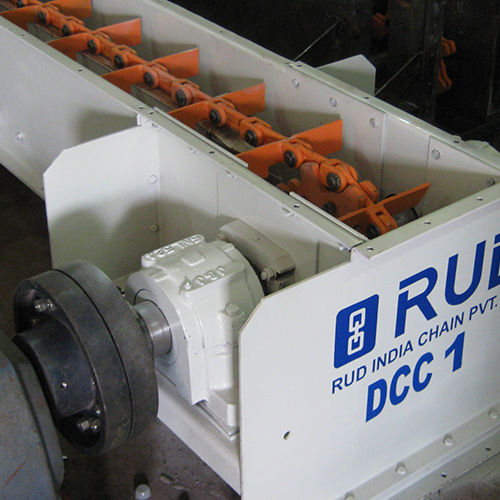

Drag chain conveyors

The standard drag transport or simply Drag chain conveyor uses two huge chains with consistently scattered paddles between them, which drag along the lower part of a container to move material. How much mass moved by every paddle is coordinated by its surface district, as well as the chain speed, and they are replaceable once they break down. The chain speed is regularly drowsy which reduces energy usage, and the whole party is easy to use, direct, and clever. Certain models can run at up to 50 ft/min with a constraint of 10 cubic feet every second at a length up to 400 feet for each drive. They are extraordinary for non-clean, non-grinding things like grain, and shakes, and that is only the start, and are regularly used as feeders for various machines. Their huge obstructions are their proclivity to wear out, as materials team up clearly with the chain and can cause issues. Similarly, the chains will unevenly reach out long term, requiring dependable upkeep to ensure suitable plans.